علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 31-8-2017

Date: 21-8-2017

Date: 14-9-2017

|

STEAM CRACKING OF HYDROCARBONS

(Production of Olefins)

The main route for producing light olefins, especially ethylene, is the steam cracking of hydrocarbons. The feedstocks for steam cracking units range from light paraffinic hydrocarbon gases to various petroleum fractions and residues.

The cracking reactions are principally bond breaking, and a substantial amount of energy is needed to drive the reaction toward olefin production. The simplest paraffin (alkane) and the most widely used feedstock for producing ethylene is ethane. As mentioned earlier, ethane is obtained from natural gas liquids. Cracking ethane can be visualized as a free radical dehydrogenation reaction, where hydrogen is a coproduct:

CH3CH3 → CH2=CH2 + H2 ΔH590°C = +143 KJ

The reaction is highly endothermic, so it is favored at higher temperatures and lower pressures. Superheated steam is used to reduce the partial pressure of the reacting hydrocarbons’ (in this reaction, ethane). Superheated steam also reduces carbon deposits that are formed by the pyrolysis of hydrocarbons at high temperatures. For example, pyrolysis of ethane produces carbon and hydrogen:

CH3CH3 → 2C + 3H2

Ethylene can also pyrolyse in the same way. Additionally, the presence of steam as a diluent reduces the hydrocarbons’ chances of being in contact with the reactor tube-wall. Deposits reduce heat transfer through the reactor tubes, but steam reduces this effect by reacting with the carbon deposits (steam reforming reaction).

C + H2O → CO + H2

Many side reactions occur when ethane is cracked. A probable sequence of reactions between ethylene and a formed methyl or an ethyl free radical could be represented:

CH2=CH2 + C˙H3 → CH3CH2C˙H2 r CH3CH=CH2 + H˙

CH2=CH2 + CH3C˙H2 → CH3CH2CH2C˙H2 → CH3CH2CH=CH2 + H˙

Propene and l-butene, respectively, are produced in this free radical reaction. Higher hydrocarbons found in steam cracking products are probably formed through similar reactions. When liquid hydrocarbons such as a naphtha fraction or a gas oil are used to produce olefins, many other reactions occur. The main reaction, the cracking reaction, occurs by a free radical and beta scission of the C-C bonds. This could be represented as:

RCH2CH2CH2R → RCH2CH2C˙H2+ R˙

RCH2CH2C˙H2 → RC˙H2 + CH2=CH2

The newly formed free radical may terminate by abstraction of a hydrogen atom, or it may continue cracking to give ethylene and a free radical. Aromatic compounds with side chains are usually dealkylated. The produced free radicals further crack to yield more olefins.

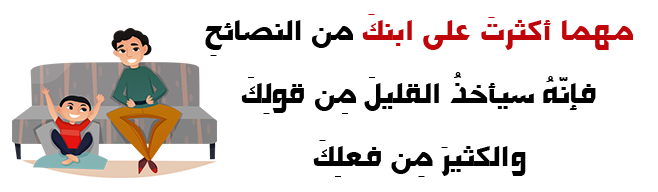

In the furnace and in the transfer line exchanger, coking is a significant problem. Catalytic coking occurs on clean metal surfaces when nickel and other transition metals used in radiant tube alloys catalyze dehydrogenation and formation of coke. Coke formation reduces product yields, increases energy consumption, and shortens coil service life. Coking is related to feedstock, temperature, and steam dilution. The radiant tubes gradually become coated with an internal layer of coke, thus raizing the tube metal temperature and increasing pressure drop through the radiant coils. When coke reaches an allowable limit as indicated by a high pressure drop, it should be removed. Coke could be reduced by adding antifoulants, which passivate the catalytic coking mechanism. The subject has been reviewed by Burns et al. Over the past 20 years, significant improvements have been made in the design and operation of high severity pyrolysis furnances. Using better alloys for tubing has enabled raising the temperature, shortening residence time and lowering pressure drop in the cracking coils. The use of cast alloys with a higher alloy content increases their long-term strength. Figure 1.1 shows the effect of alloy content on the long-term rupture stress for modified Ni- Cr-Fe alloys.

Figure 1.1. Effect of alloy content on long-term rupture stress for cast modified Ni-Cr-Fe alloys.

|

|

|

|

دراسة يابانية لتقليل مخاطر أمراض المواليد منخفضي الوزن

|

|

|

|

|

|

|

اكتشاف أكبر مرجان في العالم قبالة سواحل جزر سليمان

|

|

|

|

|

|

|

المجمع العلمي ينظّم ندوة حوارية حول مفهوم العولمة الرقمية في بابل

|

|

|