علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 22-8-2017

Date: 31-7-2017

Date: 31-8-2017

|

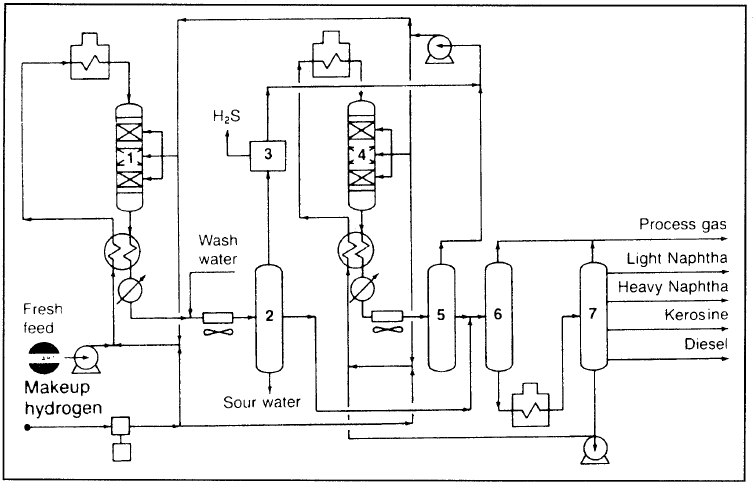

Hydrodealkylation Process

This process is designed to hydrodealkylate methylbenzenes, ethylbenzene and C9+ aromatics to benzene. The petrochemical demand for benzene is greater than for toluene and xylenes. After separating benzene from the reformate, the higher aromatics are charged to a hydrodealkylation unit. The reaction is a hydrocracking one, where the alkyl side chain breaks and is simultaneously hydrogenated. For example, toluene dealkylates to methane and benzene, while ethylbenzene produces ethane and benzene. In each case one mole of H2 is consumed:

Figure 1.1. Flow diagram of a Cheveron hydocracking unit: (1,4) reactors, (2,5) HP separators, (3) recycle scrubber (optional), (6) LP separator, (7) fractionator.

Consuming hydrogen is mainly a function of the number of benzene substituents. Dealkylation of polysubstituted benzene increases hydrogen consumption and gas production (methane). For example, dealkylating one mole xylene mixture produces two methane moles and one mole of benzene; it consumes two moles of hydrogen.

Unconverted toluene and xylenes are recycled.

|

|

|

|

دخلت غرفة فنسيت ماذا تريد من داخلها.. خبير يفسر الحالة

|

|

|

|

|

|

|

ثورة طبية.. ابتكار أصغر جهاز لتنظيم ضربات القلب في العالم

|

|

|

|

|

|

|

لتعزيز مفاهيم الابتكار والتميز المؤسسي.. أكاديمية الوارث التابعة للعتبة الحسينية تطلق برنامج (الريادة التعليمية)

|

|

|