علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

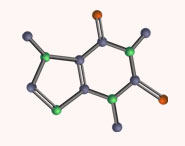

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 24-9-2017

Date: 24-9-2017

Date: 26-9-2017

|

Polyvinyl chloride (PVC)

Polyvinyl chloride (PVC) is one of the most widely used thermoplastics. It can be extruded into sheets and film and blow molded into bottles. It is used in many common items such as garden hoses, shower curtains, irrigation pipes, and paint formulations. PVC can be prepolymerized in bulk to approximately 7–8% conversion. It is then transferred to an autoclave where the particles are polymerized to a solid powder. Most vinyl chloride, however, is polymerized in suspension reactors made of stainless steel or glass-lined. The peroxide used to initiate the reaction is dispersed in about twice its weight of water containing 0.01–1% of a stabilizer such as polyvinyl alcohol.l8 In the European Vinyls Corp. process (Figure 1.1), vinyl chloride monomer (VCM) is dispersed in water and then charged with the additives to the reactor.

Figure 1.1. The European Vinyls Corp. process for producing polyvinyl chloride using suspension polymerization: (1) reactor, (2) blow-down vessels (to separate unreacted monomer), (3) stripping column, (4) reacted monomer recovery, (5) slurry centrifuge, (6) slurry drier.

It is a stirred jacketed type ranging in size between 20–105m3. The temperature is maintained between 53–70°C to obtain a polymer of a particular molecular weight. The heat of the reaction is controlled by cooling water in the jacket and by additional reflux condensers for large reactors. Conversion could be controlled between 85–95% as required by the polymer grade. At the end of the reaction, the PVC and water slurry are channelled to a blowdown vessel, from which part of unreacted monomer is recovered. The rest of the VCM is stripped, and the slurry is centrifuged to separate the polymer from both water and the initiator.

Polyvinyl chloride can also be produced in emulsion. Water is used as the emulsion medium. The particle size of the polymer is controlled using the proper conditions and emulsifier. Polymers produced by free radical initiators are highly branched with low crystallinity.

Vinyl chloride can be copolymerized with many other monomers to improve its properties. Examples of monomers used commercially are vinyl acetate, propylene, ethylene, and vinylidine chloride. The copolymer with ethylene or propylene (Tg = 80°C), which is rigid, is used for blow molding objects. Copolymers with 6–20% vinyl acetate (Tg = 50–80°C ) are used for coatings.

|

|

|

|

دراسة يابانية لتقليل مخاطر أمراض المواليد منخفضي الوزن

|

|

|

|

|

|

|

اكتشاف أكبر مرجان في العالم قبالة سواحل جزر سليمان

|

|

|

|

|

|

|

اتحاد كليات الطب الملكية البريطانية يشيد بالمستوى العلمي لطلبة جامعة العميد وبيئتها التعليمية

|

|

|