علم الكيمياء

علم الكيمياء

الكيمياء التحليلية

الكيمياء التحليلية

الكيمياء الحياتية

الكيمياء الحياتية

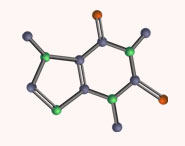

الكيمياء العضوية

الكيمياء العضوية

الكيمياء الفيزيائية

الكيمياء الفيزيائية

الكيمياء اللاعضوية

الكيمياء اللاعضوية

مواضيع اخرى في الكيمياء

مواضيع اخرى في الكيمياء

الكيمياء الصناعية

الكيمياء الصناعية |

Read More

Date: 21-8-2017

Date: 19-1-2016

Date: 22-8-2017

|

Acrylic Acid

There are several ways to produce acrylic acid. Currently, the main process is the direct oxidation of acrolein over a combination molybdenum- vanadium oxide catalyst system. In many acrolein processes, acrylic acid is made the main product by adding a second reactor that oxidizes acrolein to the acid. The reactor temperature is approximately 250°C:

Acrylic acid is usually esterified to acrylic esters by adding an esterification reactor. The reaction occurs in the liquid phase over an ion exchange resin catalyst. An alternative route to acrylic esters is via a β-propiolactone intermediate.

The lactone is obtained by the reaction of formaldehyde and ketene, a dehydration product of acetic acid:

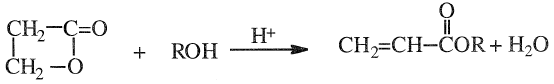

The acid-catalyzed ring opening of the four-membered ring lactone in the presence of an alcohol produces acrylic esters:

Acrylic acid and its esters are used to produce acrylic resins. Depending on the polymerization method, the resins could be used in the adhesive, paint, or plastic industry.

|

|

|

|

التوتر والسرطان.. علماء يحذرون من "صلة خطيرة"

|

|

|

|

|

|

|

مرآة السيارة: مدى دقة عكسها للصورة الصحيحة

|

|

|

|

|

|

|

نحو شراكة وطنية متكاملة.. الأمين العام للعتبة الحسينية يبحث مع وكيل وزارة الخارجية آفاق التعاون المؤسسي

|

|

|