تاريخ الفيزياء

علماء الفيزياء

الفيزياء الكلاسيكية

الميكانيك

الديناميكا الحرارية

الكهربائية والمغناطيسية

الكهربائية

المغناطيسية

الكهرومغناطيسية

علم البصريات

تاريخ علم البصريات

الضوء

مواضيع عامة في علم البصريات

الصوت

الفيزياء الحديثة

النظرية النسبية

النظرية النسبية الخاصة

النظرية النسبية العامة

مواضيع عامة في النظرية النسبية

ميكانيكا الكم

الفيزياء الذرية

الفيزياء الجزيئية

الفيزياء النووية

مواضيع عامة في الفيزياء النووية

النشاط الاشعاعي

فيزياء الحالة الصلبة

الموصلات

أشباه الموصلات

العوازل

مواضيع عامة في الفيزياء الصلبة

فيزياء الجوامد

الليزر

أنواع الليزر

بعض تطبيقات الليزر

مواضيع عامة في الليزر

علم الفلك

تاريخ وعلماء علم الفلك

الثقوب السوداء

المجموعة الشمسية

الشمس

كوكب عطارد

كوكب الزهرة

كوكب الأرض

كوكب المريخ

كوكب المشتري

كوكب زحل

كوكب أورانوس

كوكب نبتون

كوكب بلوتو

القمر

كواكب ومواضيع اخرى

مواضيع عامة في علم الفلك

النجوم

البلازما

الألكترونيات

خواص المادة

الطاقة البديلة

الطاقة الشمسية

مواضيع عامة في الطاقة البديلة

المد والجزر

فيزياء الجسيمات

الفيزياء والعلوم الأخرى

الفيزياء الكيميائية

الفيزياء الرياضية

الفيزياء الحيوية

الفيزياء العامة

مواضيع عامة في الفيزياء

تجارب فيزيائية

مصطلحات وتعاريف فيزيائية

وحدات القياس الفيزيائية

طرائف الفيزياء

مواضيع اخرى

OPTICS

المؤلف:

Mark Csele

المصدر:

FUNDAMENTALS OF LIGHT SOURCES AND LASERS

الجزء والصفحة:

p319

14-4-2016

1732

OPTICS

The simplest conventional laser diodes can use the cleaved surfaces of the semiconductor crystal as cavity reflectors. The difference of the index of refraction of the semiconductor material to the surrounding air forms a reflector with an approximately 33%reflection. Although this may seem low, semiconductor lasers typically exhibit a high-enough gain to overcome such losses. For higher efficiency, the rear surface of the semiconductor laser can be coated with a multilayer dielectric mirror to reflect almost 100% of the light emitted in that direction. The front optic on such a laser is still usually an uncoated, cleaved surface. With a short active layer, the gain is much lower in VCSELs than in edge-emitting lasers, so that dielectric mirrors fabricated from multiple layers of dielectrics, alternating quarter-wavelength-thick layers of high- and low-index-of-refraction materials, are the rule for both cavity optics for these lasers. Mirrors fabricated in such a way are highly wavelength selective, with the wavelength corresponding to the maximum gain of the semiconductor device.

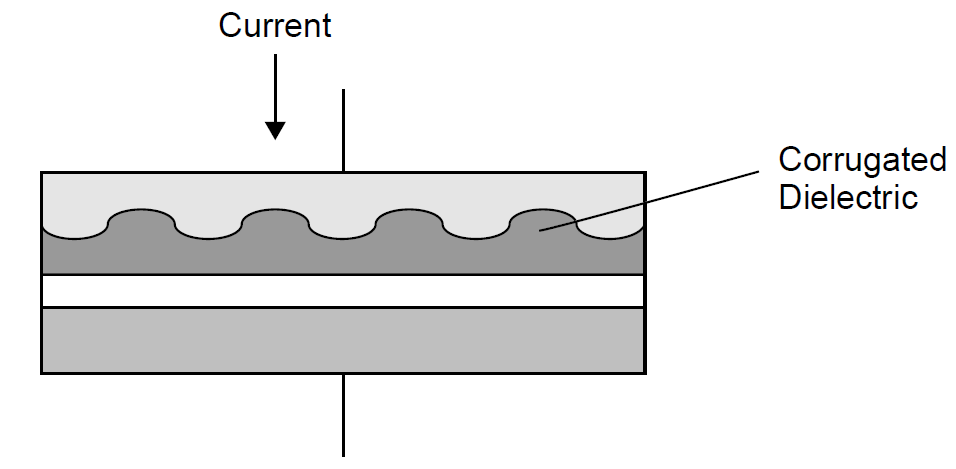

The inherent spectral width of semiconductor lasers is quite large compared with, say, a gas laser with a typical multimode diode having a spectral width of 2 to 4 nm. To reduce the spectral width, wavelength-selective optics may be employed in a manner similar to that used for other lasers: namely, the use of a grating in place of the HR. Given the tiny dimensions of a semiconductor laser, though, implementation of a discrete diffraction grating is difficult, so the grating may be constructed as an elongated structure called a distributed Bragg reflector (DBR). Such a reflector resembles a corrugated surface (like the center of cardboard) manufactured from dielectric materials. Reflection of waves at the interface between two materials of different indexes of refraction leads to constructive interference at

Figure 1.1. Distributed Bragg reflector on a laser diode.

Figure 1.2. Distributed feedback laser diode.

a single well-defined wavelength (determined by the distance between peaks in the corrugation). Such a reflector acts much like a high-performance dielectric mirror, with the specific wavelength of maximum reflectivity called the Bragg wavelength.

Taking the DBR scheme one step further, the confining layer (top of bottom) on one side of a regular laser diode can be replaced with a Bragg reflector fabricated in a manner similar to that of the DBR. In such a manner, light confined within the cavity is wavelength-selected so that only a single wavelength (where the reflector is resonant) is amplified within the laser. This corrugated structure reflects partially at each interface between the materials of differing refractive index, so optical feedback is distributed throughout the cavity [hence the term distributed feedback (DFB)]. The grating, again a corrugated surface composed of dielectric materials, is fabricated into the structure of the diode itself and is distributed over a considerably longer length than a traditional grating stretching over the entire length of the device (Figure 1.2). A discrete HR and OC are not required on such a device, and like the DBR laser, the wavelength of the grating determined by the spacing of the corrugations and the resulting spectral width of the output can be as low as 0.1 nm.

الاكثر قراءة في بعض تطبيقات الليزر

الاكثر قراءة في بعض تطبيقات الليزر

اخر الاخبار

اخر الاخبار

اخبار العتبة العباسية المقدسة

الآخبار الصحية

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة "المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة

"المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة (نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)

(نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)