تاريخ الفيزياء

علماء الفيزياء

الفيزياء الكلاسيكية

الميكانيك

الديناميكا الحرارية

الكهربائية والمغناطيسية

الكهربائية

المغناطيسية

الكهرومغناطيسية

علم البصريات

تاريخ علم البصريات

الضوء

مواضيع عامة في علم البصريات

الصوت

الفيزياء الحديثة

النظرية النسبية

النظرية النسبية الخاصة

النظرية النسبية العامة

مواضيع عامة في النظرية النسبية

ميكانيكا الكم

الفيزياء الذرية

الفيزياء الجزيئية

الفيزياء النووية

مواضيع عامة في الفيزياء النووية

النشاط الاشعاعي

فيزياء الحالة الصلبة

الموصلات

أشباه الموصلات

العوازل

مواضيع عامة في الفيزياء الصلبة

فيزياء الجوامد

الليزر

أنواع الليزر

بعض تطبيقات الليزر

مواضيع عامة في الليزر

علم الفلك

تاريخ وعلماء علم الفلك

الثقوب السوداء

المجموعة الشمسية

الشمس

كوكب عطارد

كوكب الزهرة

كوكب الأرض

كوكب المريخ

كوكب المشتري

كوكب زحل

كوكب أورانوس

كوكب نبتون

كوكب بلوتو

القمر

كواكب ومواضيع اخرى

مواضيع عامة في علم الفلك

النجوم

البلازما

الألكترونيات

خواص المادة

الطاقة البديلة

الطاقة الشمسية

مواضيع عامة في الطاقة البديلة

المد والجزر

فيزياء الجسيمات

الفيزياء والعلوم الأخرى

الفيزياء الكيميائية

الفيزياء الرياضية

الفيزياء الحيوية

الفيزياء العامة

مواضيع عامة في الفيزياء

تجارب فيزيائية

مصطلحات وتعاريف فيزيائية

وحدات القياس الفيزيائية

طرائف الفيزياء

مواضيع اخرى

STRUCTURE OF A LONGITUDINAL CO2 LASER

المؤلف:

Mark Csele

المصدر:

FUNDAMENTALS OF LIGHT SOURCES AND LASERS

الجزء والصفحة:

p286

25-3-2016

1941

STRUCTURE OF A LONGITUDINAL CO2 LASER

Used primarily for lower-power lasers (low power being a relative term, since it is used commonly with lasers up to 1 kW), a longitudinal CO2 laser resembles any other type of gas laser: a glass plasma tube of reasonably large diameter (often 10 to 15 mm) with an integral water cooling jacket and either internal or external optics. In some lasers the cavity reflectors are mounted directly to the laser tube, like that of a HeNe laser, only mounted on flexible metal bellows, allowing adjustment. A laser with external optics will often feature windows (IR transparent, of course) on the ends of the tube, mounted in a similar bellows arrangement.

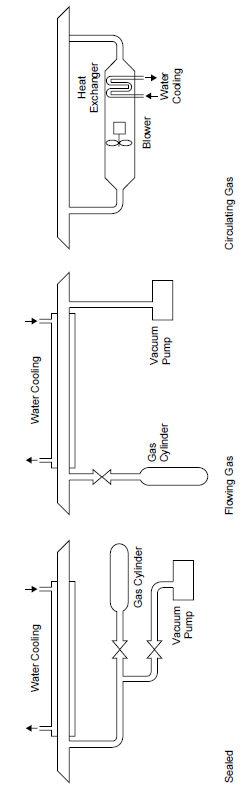

In longitudinal lasers gas pressures are low, usually between 15 and 60 torr. There are several variations on this type of laser based on the gas flow used. Some lasers of this type are sealed, regenerating lasing gas dissociated in the process (below) within the operating plasma tube itself. The gas mixture usually has a finite lifetime, with one gas fill lasting from one to eight hours of operation. The tube is then evacuated and refilled with a fresh gas mixture. Often, an hour-meter is installed on such a laser, indicating the amount of time that a fill has been used.

As the CO2 laser operates, carbon dioxide molecules dissociate, that is, are literally ripped apart, leaving oxygen and carbon monoxide. Soon the partial pressure of CO2 drops in the laser tube, as does gain. To overcome this problem one can (1) use flowing gas to remove CO and replace it with a fresh supply of CO2 (as done in flowing gas lasers, described next); (2) use a hot nickel catalyst within the tube, which recombines CO and oxygen into CO2; or (3) add water vapor to the tube.

In the case of water vapor a reaction occurs in which CO combines with H2O to produce CO2. Water vapor is also formed when hydrogen and oxygen recombine in the tube. This approach is useful in sealed lasers, but care must be taken in designing the tube so that windows and other optical components are not hygroscopic. Hygroscopic materials absorb water vapor and in doing so, become cloudy and absorb IR radiation (with disastrous consequences). Salt crystals (sodium chloride) transmit IR radiation well at 10.6 μm but are quite hygroscopic and so would be a poor material for a tube employing water vapor. Other materials, such as zinc selenide or germanium, would be a better choice. Although an option, addition of water vapor is not a popular approach for commercial lasers, but the alternative, incorporating a nickel catalyst into the tube, is. This approach is used with many sealed tubes simply by fabricating the tube electrodes from nickel. Combined with the heat from the discharge, this catalyzes CO back into CO2. Sealed lasers are typically restricted to power levels of about 100 W.

Flowing gas lasers admit fresh gas at one end of the tube and evacuate it with a vacuum pump at the other. Flow rates may vary from slow (1 L/min) to moderate (20 L/min) with control of gas pressure usually accomplished by restricting the flow rate via a needle valve. The required rate of flow of an axial flow laser depends on the tube diameter and the power levels involved. Flowing gas both replaces dissociated gas molecules (CO) and removes impurities generated through the discharge in the tube (especially in a very high power discharge, where the electrodes can liberate large quantities of gases as they heat). This approach is most often used with lasers under 1 kW. Higher-powered longitudinal lasers are often circulating gas lasers in which gas continually flows through the tube and is recycled, passing it through a heat exchanger in the process. Fresh gas is often leaked into such a system as well to replenish. Figure 1.1 depicts the variations of longitudinal laser structures.

Water cooling of any CO2 laser is the rule not only to prevent damage to the discharge tube but also to remove the thermal population from the lower lasing levels. In a sealed or flowing-gas laser, cooling is accomplished by conduction of heat through the tube walls, a coaxial water jacket around the plasma tube serving to remove the heat from molecules of gas colliding with the tube walls (conduction of heat being one of the primary roles of helium in the tube). In a circulating gas laser an integral heat exchanger (often resembling a miniature automotive radiator) performs this task, with convection as the heat removal mechanism. Circulating gas

Figure 1.1. Longitudinal laser structures.

Figure 1.2. DC excited laser.

lasers can utilize larger tube diameters than flowing types since the tube walls are not used as a heat exchanger.

Laser gain is also a function of tube diameter since the entire system relies on helium to remove heat from the system and depopulate the lower lasing levels. Use of a larger-diameter tube requires that helium atoms travel farther from the center of the tube to the tube walls in order to dump heat there. Higher gains thus occur with small-diameter tubes, although even the smallest tubes are still much larger than other gas lasers, such as ion lasers.

Figure 1.2 shows a twin-tube research laser capable of power outputs of 100 W. Each tube is about 1.5 m long and the arrangement is a folded one in which the tubes are optically in series with the HR and OC at the same end of the laser. Two steering mirrors at the far end of the laser bend the beam between the two tubes so that they are optically connected (this also means that four mirrors must be aligned on this laser, not just the OC and HR). This folded approach is often done to decrease the overall length of the laser, with some industrial lasers featuring four or more tubes in series. The other reason is to allow the use of shorter electrical discharge paths in these plasma tubes to decrease the operating voltage. Another approach to lower operating voltage is to use multiple electrodes in a single tube.

الاكثر قراءة في بعض تطبيقات الليزر

الاكثر قراءة في بعض تطبيقات الليزر

اخر الاخبار

اخر الاخبار

اخبار العتبة العباسية المقدسة

الآخبار الصحية

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة

قسم الشؤون الفكرية يصدر كتاباً يوثق تاريخ السدانة في العتبة العباسية المقدسة "المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة

"المهمة".. إصدار قصصي يوثّق القصص الفائزة في مسابقة فتوى الدفاع المقدسة للقصة القصيرة (نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)

(نوافذ).. إصدار أدبي يوثق القصص الفائزة في مسابقة الإمام العسكري (عليه السلام)