Preparation of the Transition Elements

المؤلف:

LibreTexts Project

المؤلف:

LibreTexts Project

المصدر:

................

المصدر:

................

الجزء والصفحة:

.................

الجزء والصفحة:

.................

20-5-2020

20-5-2020

1701

1701

Preparation of the Transition Elements

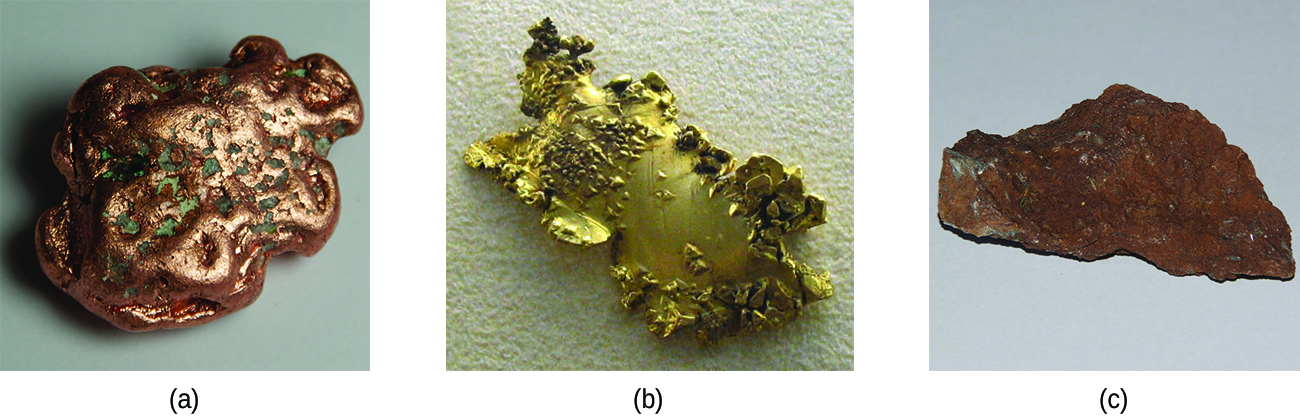

Ancient civilizations knew about iron, copper, silver, and gold. The time periods in human history known as the Bronze Age and Iron Age mark the advancements in which societies learned to isolate certain metals and use them to make tools and goods. Naturally occurring ores of copper, silver, and gold can contain high concentrations of these metals in elemental form (Figure 1.1). Iron, on the other hand, occurs on earth almost exclusively in oxidized forms, such as rust (Fe2O3). The earliest known iron implements were made from iron meteorites. Surviving iron artifacts dating from approximately 4000 to 2500 BC are rare, but all known examples contain specific alloys of iron and nickel that occur only in extraterrestrial objects, not on earth. It took thousands of years of technological advances before civilizations developed iron smelting, the ability to extract a pure element from its naturally occurring ores and for iron tools to become common.

Figure 1.1 : Transition metals occur in nature in various forms. Examples include (a) a nugget of copper, (b) a deposit of gold, and (c) an ore containing oxidized iron.

Generally, the transition elements are extracted from minerals found in a variety of ores. However, the ease of their recovery varies widely, depending on the concentration of the element in the ore, the identity of the other elements present, and the difficulty of reducing the element to the free metal.

In general, it is not difficult to reduce ions of the d-block elements to the free element. Carbon is a sufficiently strong reducing agent in most cases. However, like the ions of the more active main group metals, ions of the f-block elements must be isolated by electrolysis or by reduction with an active metal such as calcium.

We shall discuss the processes used for the isolation of iron, copper, and silver because these three processes illustrate the principal means of isolating most of the d-block metals. In general, each of these processes involves three principal steps: preliminary treatment, smelting, and refining.

- Preliminary treatment. In general, there is an initial treatment of the ores to make them suitable for the extraction of the metals. This usually involves crushing or grinding the ore, concentrating the metal-bearing components, and sometimes treating these substances chemically to convert them into compounds that are easier to reduce to the metal.

- Smelting. The next step is the extraction of the metal in the molten state, a process called smelting, which includes reduction of the metallic compound to the metal. Impurities may be removed by the addition of a compound that forms a slag—a substance with a low melting point that can be readily separated from the molten metal.

- Refining. The final step in the recovery of a metal is refining the metal. Low boiling metals such as zinc and mercury can be refined by distillation. When fused on an inclined table, low melting metals like tin flow away from higher-melting impurities. Electrolysis is another common method for refining metals.

الاكثر قراءة في مواضيع عامة في الكيمياء اللاعضوية

الاكثر قراءة في مواضيع عامة في الكيمياء اللاعضوية

اخر الاخبار

اخر الاخبار

اخبار العتبة العباسية المقدسة